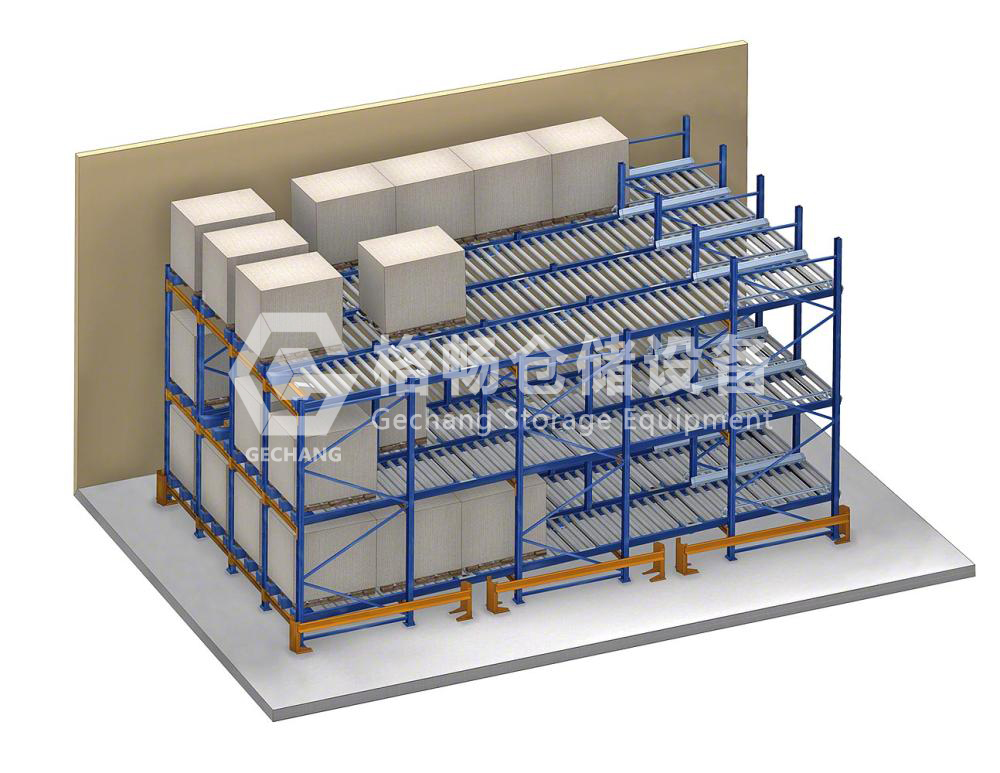

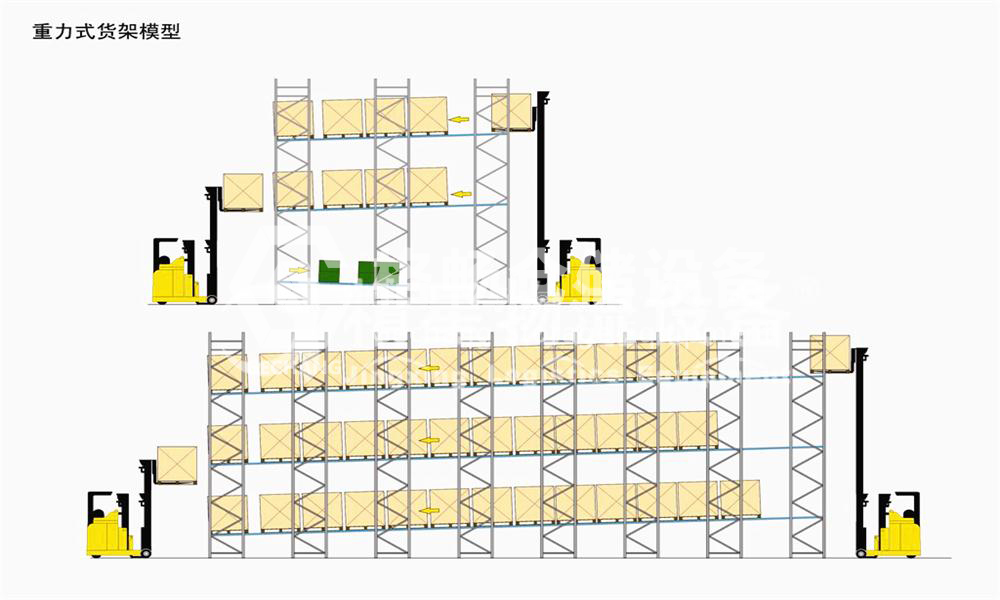

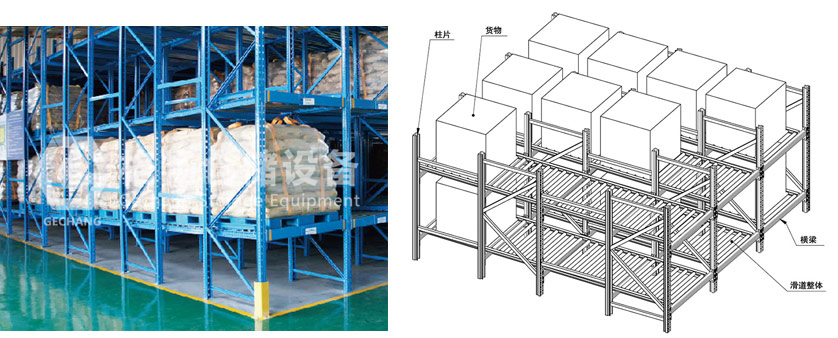

Gravity shelves by pallet racking descended, the rolling wheel tracks or bottom tray, orbit in a certain slope (about 3 DHS), using the weight of the goods, realize the first in first out of the goods, one into the other, is suitable for large quantity, the first in first out of the same goods storage, high space utilization, especially applicable to a certain quality assurance period, should not be the backlog of goods for a long time. Shelves total depth (that is, the guide rail length) should not be too large, or not to use up and down "blind Angle" will be larger, influence space utilization, and elongation of the ramp will slide in the controllable is poorer, falling impact is bigger, easy cause decline, block, tray of the tilting of the goods. To make the slide smoothly, such as a long ramp, should be set up in the middle damping device, in order to make pallet fell to the bottom when not tilting because of the impact force is too large, should be a minimum of the ramp in buffer device, for ease of pickup also need low-end pallet automatic separation device is set at the track, so this system will be rather big difficulty in the design, manufacture, installation, the cost is higher. This kind of shelf should not be too high, generally within 6m, the weight of goods in a single pallet is generally within 1000kg, otherwise its reliability and operability will be reduced. This kind of shelf system is generally applicable to a small variety of goods in large quantities. This kind of rack system to tray also to have certain request, rigidity and bearing capacity of the pallet, material and so on all has certain requirements, general wooden tray is not suitable for, mostly for plastic and steel pallet. In addition, this kind of shelf system also has high requirements on the ground and high requirements on its flatness and ground endurance, especially the uneven subsidence of the ground will have a great impact on it.